Rotary Copper Extrusion Machine

1.The raw material specifications of Rotary Copper Extrusion Machine are unified, and the material preparation is convenient and simple

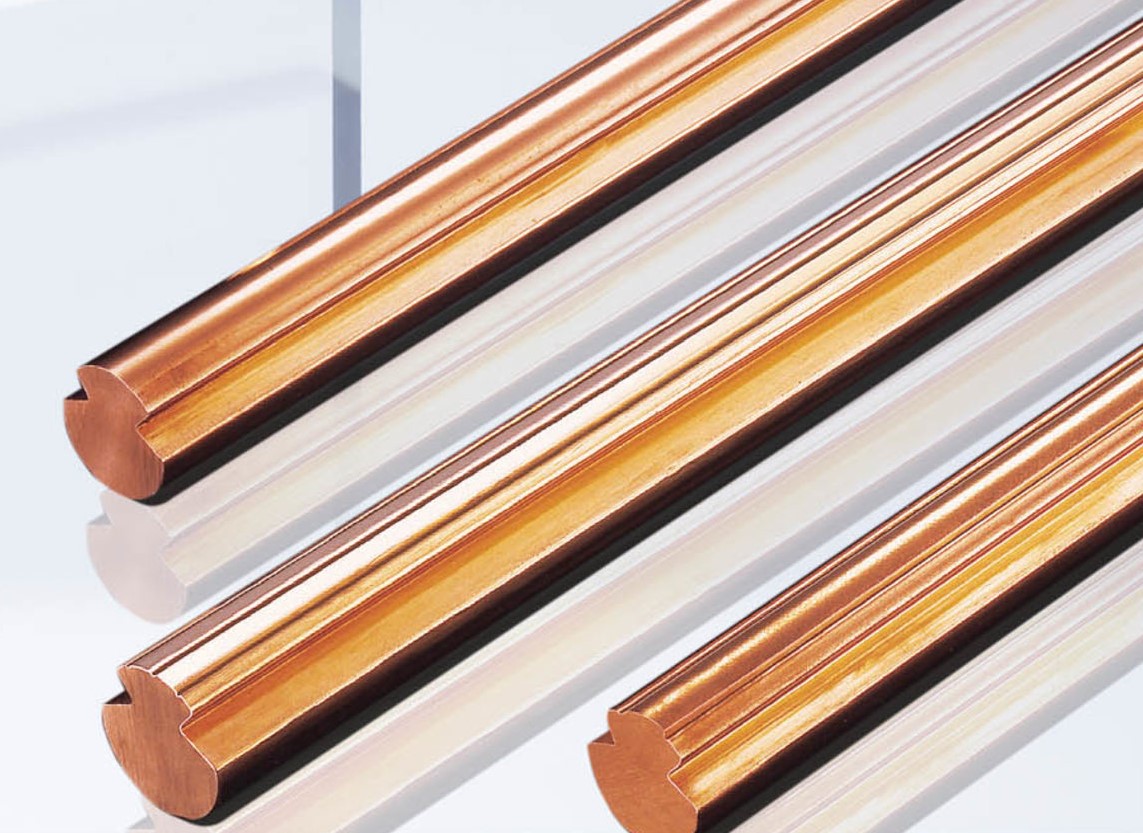

2.Rotary Copper Extrusion Machine has high surface finish, high dimensional accuracy and stable performance

3.Rotary Copper Extrusion Machine can obtain excellent mechanical properties and microstructure, and the product has good electrical conductivity

Use of Rotary Copper extrusion Machine:

Rotary Copper extrusion Machine can produce various specifications of copper bars, copper bars, copper profiles

Specifications of Rotary Copper Extrusion Machine :

Model | TLJ350 | TLJ400 | TLJ500 | TLJ630 |

Nominal diameter of extrusion wheel (mm) | 350 | 400 | 500 | 630 |

Main motor power (kw) | 160 | 250 | 355 | 600 |

Copper rod diameter (mm) | 16 | 20 | 25 | 30 |

Product maximum width (mm) | 100 | 170 | 260 | 320 |

Round bar product diameter (mm) | 4.5~50 | 8~90 | 12~100 | 12~100 |

Product cross-sectional area (mm²) | 15~1000 | 75~2000 | 300~3200 | 600~6400 |

Productivity (kg/h) | 780 | 1200 | 1800 | 2800 |

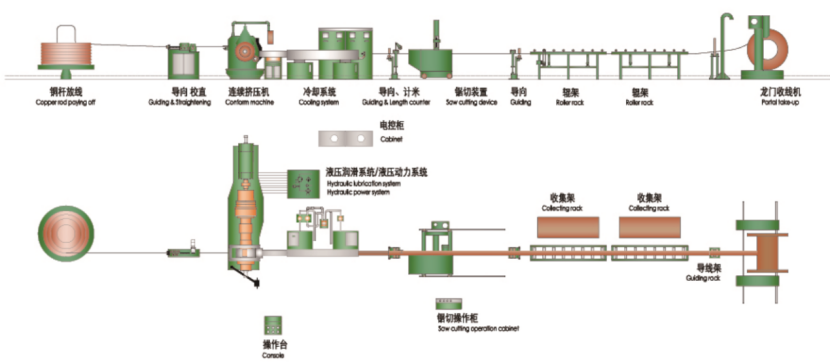

Rotary Copper Extrusion Machine production line layout:

Our advantages: advanced manufacturing, scientific management

Advanced processing methods and strict processing technology ensure the excellent quality and durable life of Konform equipment. The equipment is fully debugged before leaving the factory, and there is absolutely no flaw in the customer.

We have established a strict supply chain management system: raw materials and supporting components are provided by well-known domestic and foreign companies, and electrical components are all made of first-class brands at home and abroad