Continuous Extrusion Production Line for Copper Wire

1. Continuous Extrusion Production Line for Copper Wire has high production efficiency and low energy consumption

2. Continuous Extrusion Production Line for Copper Wire has a high degree of automation and good stability and reliability

3. Continuous Extrusion Production Line for Copper Wire no heating and pickling, no pollutant discharge, green and environmental protection

Main uses of continuous production line for copper wire:

Can produce copper flat wire, small copper bus, commutator ladder, round wire and other copper conductors.

Specifications of Continuous Extrusion Machine for Magnet Wire:

| Model | TLJ300 | TLJ300H | TLJ350 |

| Nominal diameter of extrusion wheel(mm) | 300 | 300 | 350 |

| Main motor power(kw) | 90 | 110 | 160 |

| Copper rod diameter(mm) | 12.5 | 12.5 | 16 |

| Maximum width of flat wire products(mm) | 40 | 30 | 100 |

| Minimum diameter of round product(mm) | 2.6 | 2.6 | 4.5~50 |

| Cross-sectional area of flat wire products(mm2) | 5~200 | 5~150 | 15~1000 |

| Efficiency(kg/h) | 480 | 900 | 780 |

The Principle of Continuous Extrusion:

The metal rod material is dragged into the continuously rotating extrusion wheel under the friction force of the wheel groove. When it reaches abutment, the rod material is forced to change direction and enter the chamber from the radial direction. With the high temperature and pressure caused by friction and deformation reaching the plastic deformation condition, the material is extruded from the die opening to form solid or hollow section products.

Main uses of the Continuous Extrusion Machine for Magnet Wire:

Production of copper flat wires, small copper busbars, commutator ladders, round wires and other copper conductors

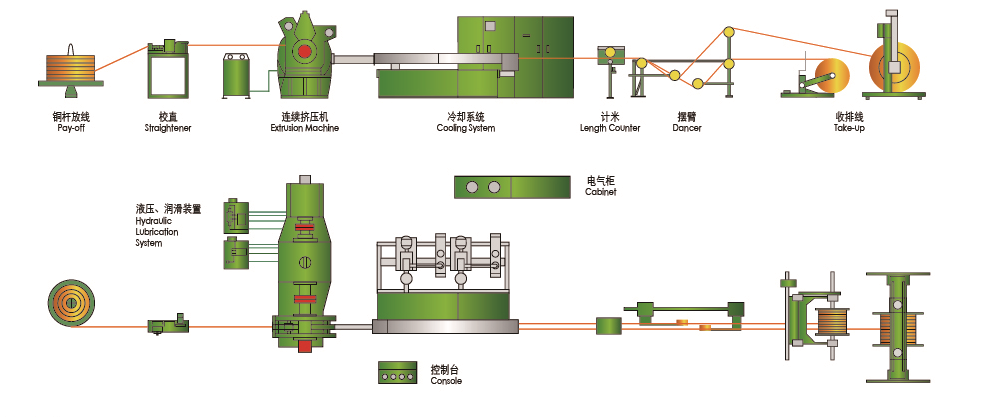

Production line layout

About us:

Originally established in 1993, Dalian Konform Technical Company, Ltd. is a world-leading provider of the continuous extrusion technology and equipment. Our research and development history in this area dated back to 1984. In over thirty years, we have provided highly efficient solutions for continuous extrusion, continuous cladding and continuous sheathing to our clients in the field of non-ferrous metal processing and cable manufacturing.

Building on over thirty patented technical innovations, Dalian Konform have developed twenty-four different models under three product categories (continuous extrusion, continuous cladding and continuous sheathing for copper and aluminum). We are certified to ISO 9001 standard and our products comply with EU CE marking. As of 2020, we have designed and manufactured more than 1500 production lines for our clients in 52 countries covering all six continents. They are widely used to produce AS wire, OPGW, aluminum sheathing of power cable, copper flat wire, copper bus bar, copper strip blank, aluminum tube, aluminum conductor etc.