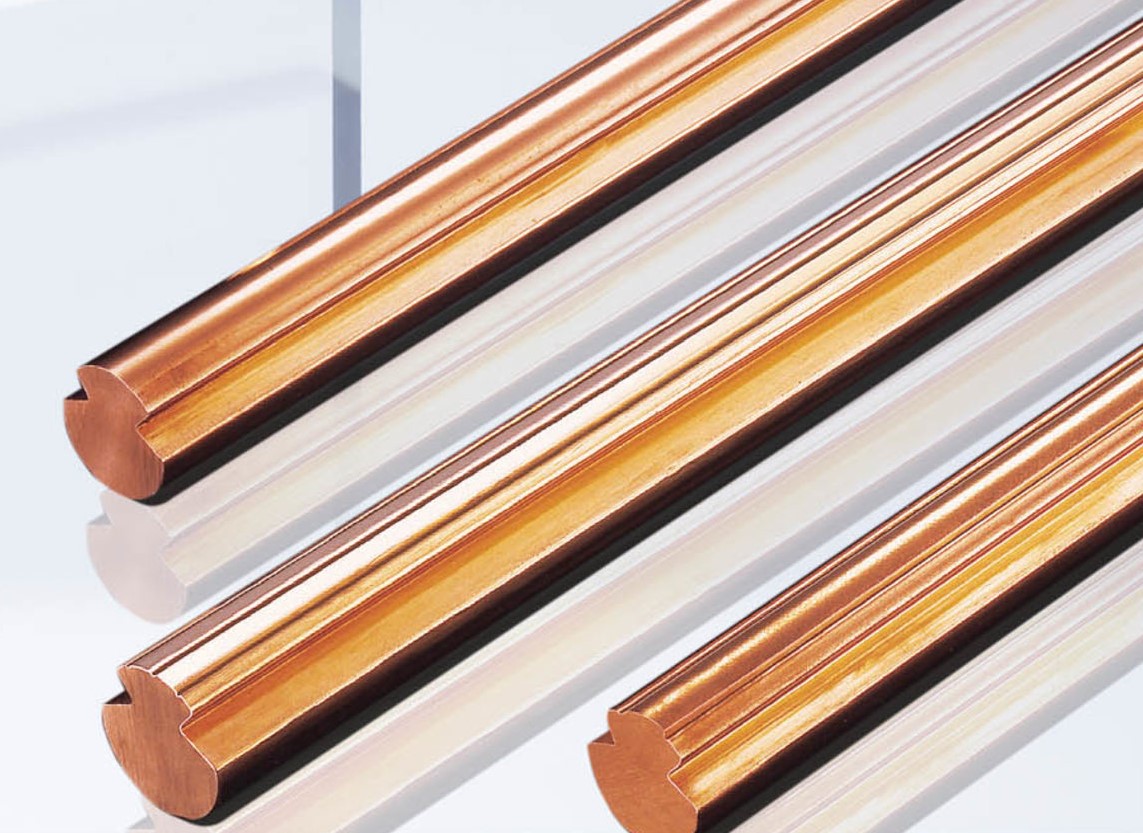

Extrusion Machinery for Copper

1.The raw material specifications of Extrusion Machinery for Copper are unified, and the material preparation is convenient and simple

2.Extrusion Machinery for Copper has high surface finish, high dimensional accuracy and stable performance

3.Extrusion Machinery for Copper can obtain excellent mechanical properties and microstructure, and the product has good electrical conductivity

The main purpose of Extrusion Machinery for Copper is to produce various specifications of copper bars, copper bars and copper profiles.

Specifications of Extrusion Machinery for Copper :

Model | TLJ350 | TLJ400 | TLJ500 | TLJ630 |

Nominal diameter of extrusion wheel (mm) | 350 | 400 | 500 | 630 |

Main motor power (kw) | 160 | 250 | 355 | 600 |

Copper rod diameter (mm) | 16 | 20 | 25 | 30 |

Product maximum width (mm) | 100 | 170 | 260 | 320 |

Round bar product diameter (mm) | 4.5~50 | 8~90 | 12~100 | 12~100 |

Product cross-sectional area (mm²) | 15~1000 | 75~2000 | 300~3200 | 600~6400 |

Productivity (kg/h) | 780 | 1200 | 1800 | 2800 |

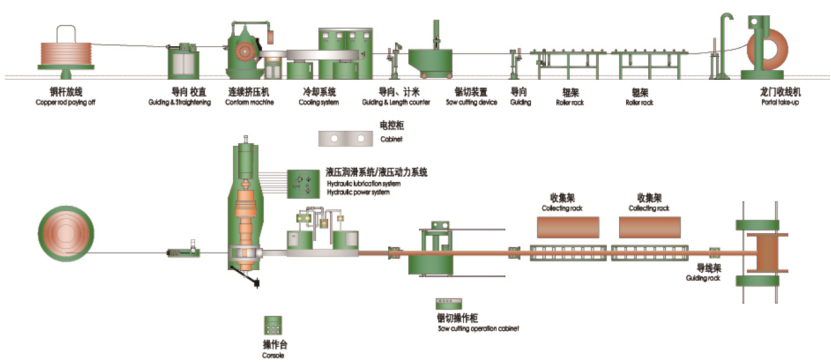

Extrusion Machinery for Copper production line layout:

Our advantages: advanced manufacturing, scientific management

Advanced processing methods and strict processing technology ensure the excellent quality and durable life of Konform equipment. The equipment is fully debugged before leaving the factory, and there is absolutely no flaw in the customer.

We have established a strict supply chain management system: raw materials and supporting components are provided by well-known domestic and foreign companies, and electrical components are all made of first-class brands at home and abroad

our service

Dalian Konform Technology Co., Ltd. has a high-quality customer service team, which is closely connected and communicated from installation and commissioning to after-sales service, quickly solves customers' equipment and process problems, shares the latest research and development results in a timely manner, and accurately provides various tooling accessories, Finished molds and all accessories for continuous extrusion presses.

At the same time, we will often conduct professional skills training for employees, and professionals will guide you how to use the product and how to solve problems when testing the product, so as to provide you with better service guarantee