Continuous Extrusion Production Line for Copper Alloy

1.The Continuous Extrusion Production Line for Copper Alloy is designed with high precision and the extrusion speed precision is controllable

2.The Continuous Extrusion Production Line for Copper Alloy has a high degree of automation and intelligent production, reducing the requirements for operators and maintenance personnel

3.Continuous Extrusion Production Line for Copper Alloy with mature structure and low failure rate

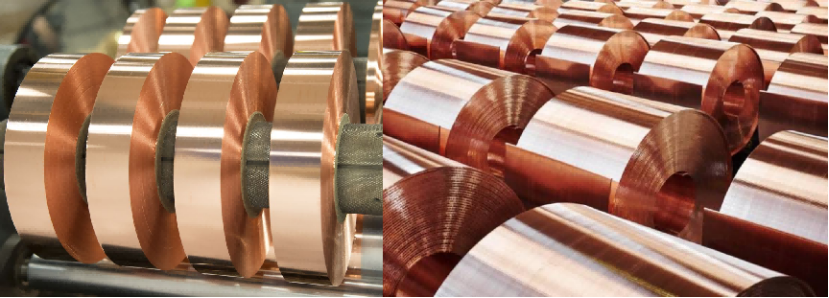

Purpose of Continuous Extrusion Production Line for Copper Alloy:

The production process of Continuous Extrusion Production Line for Copper Alloy is simple, the mold is directly formed without mold matching, and it is easy to replace. It is mainly used to produce various specifications of copper bars, copper bars, and profiles.

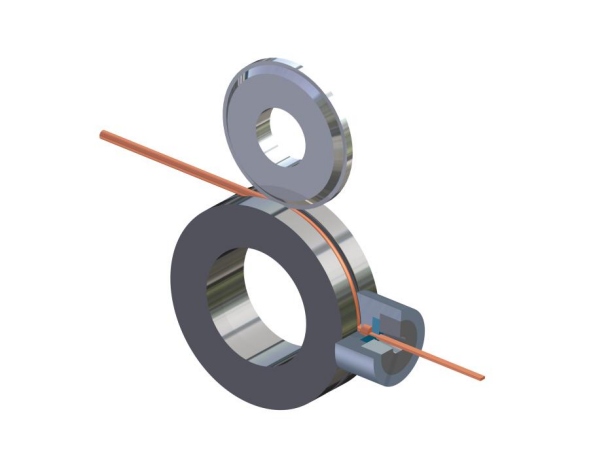

Schematic diagram of continuous extrusion principle:

Specifications of Continuous Extrusion Production Line for Copper Alloy:

| Model | TLJ400 | TLJ500 |

| Nominal diameter of extrusion wheel (mm) | 400 | 500 |

| Main motor power (kW) | 250 | 355 |

| Diameter of copper rod (mm) | 20 | 25 |

| Maximum width of product (mm) | 170 | 260 |

| Diameter of round rod product (mm)/Maximum aspect ratio (b/a) | 8~90 | 12~100 |

| Product cross-sectional area (mm2)/Copper strip thickness (mm) | 75~2000 | 300~3200 |

| Productivity (kg/h) | 1200 | 1800 |

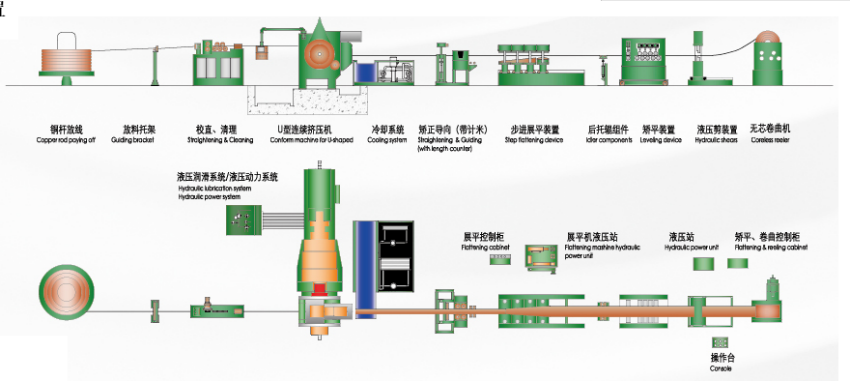

Production line layout of Continuous Extrusion Production Line for Copper Alloy

Our technical support:

Customer demand is our service content. We attach great importance to pre-sales service, strive to achieve personalized customization, and meet customers' needs for extruding new materials and producing new products using continuous extrusion technology. To this end, the Konform R&D Center is equipped with a complete set of test equipment from 250 to 630, which can carry out process tests in advance according to customer requirements, so that customers can eliminate doubts and launch new projects with peace of mind.

We have a high-quality after-sales service team with rich professional knowledge and practical experience, provide customers with technical advice around the clock, and solve various problems of customers on site.

Our office environment is transparent, bright, clean and tidy. It can accommodate up to 100 people working at the same time. The company consists of: Administration Department, Finance Department, Sales Department, Technology Center, R&D Center, Personnel Department, General Affairs Department, Production Department, etc. There is also a tea room to provide employees with delicious snacks such as coffee and afternoon tea. The simple and comfortable atmosphere allows everyone to devote themselves to their work.

As a leader in continuous extrusion equipment, we are committed to continuous research and development of new technologies, providing customers with high-quality products and services, and creating more space for employees to play there.