Sheathing Maching for Aluminum Tube

1.Sheathing Maching for Aluminum Tube saves energy and material, saves investment

2. Sheathing Maching for Aluminum Tube is environmentally friendly and green manufacturing

3. Sheathing Maching for Aluminum Tube has good product quality and high production efficiency

4. Sheathing Maching for Aluminum Tube has intelligent control and high degree of automation

Applications of Sheathing Maching for Aluminum Tube:

Production of aluminum-clad steel wires, manufacture of aluminum sheaths for cables and optical cables, including cable television coaxial cables (CATV), optical fiber composite overhead ground wires (OPGW), communication signal cables, fire-resistant cables, and aluminum sheaths for extra-high voltage cables

Specifications of Sheathing Maching for Aluminum Tube:

| Model | SLB350 | SLB400 | SSLB500 |

| Extrusion wheel diameter (mm) | 350 | 400 | 2×500 |

| Motor power (kW) | 160 | 250 | 600 |

| Aluminum rod diameter (mm) | 2×9.5 | 2×9.5/2×12 | 4×15 |

| Wire diameter (mm) | 4~28 | 8~46 | 50~160 |

| Thickness of sheath (mm) | 0.6~3 | 0.6~3 | 2~4 |

| Outer diameter of sheath (mm) | 6~30 | 20~50 | 60~180 |

| Maximum production line speed (m/min) | 60 | 60 | 12 |

Features of Sheathing Maching for Aluminum Tube:

1.Sheathing Maching for Aluminum Tube eliminates the hot working and annealing process in the old process, greatly reduces the consumption of raw materials, and greatly improves the utilization rate of materials

2. Sheathing Maching for Aluminum Tube has no pickling process and no pollutant discharge

3. Sheathing Maching for Aluminum Tube can continuously produce large lengths with high production efficiency, and the products have high dimensional accuracy and good finish

4.Sheathing Maching for Aluminum Tube is suitable for both mass production and small batch production and multi-variety production

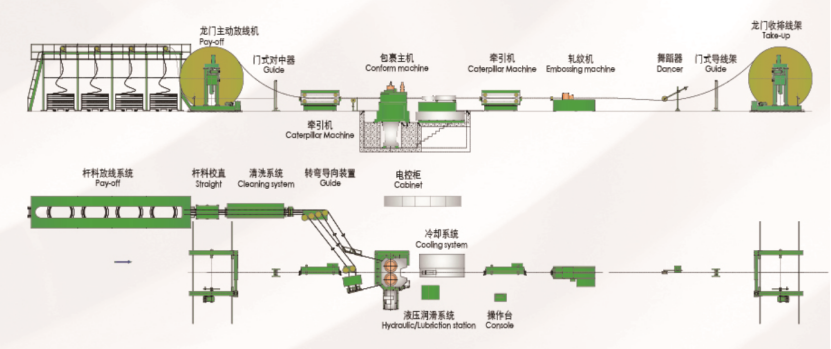

Production line layout of Sheathing Maching for Aluminum Tube:

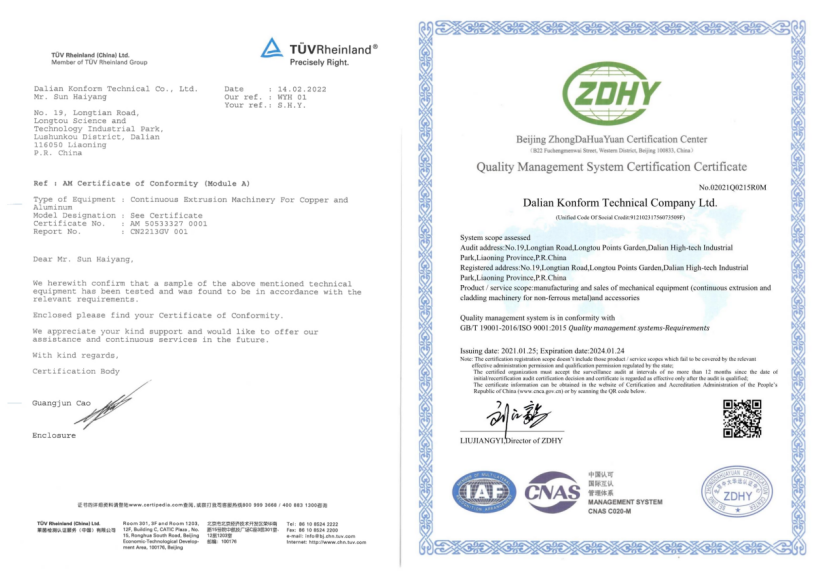

Our certificate:

Dalian Konform Technology Co., Ltd. is the first in my country to successfully develop three series of 250, 300, 350, 400, 500, 550 and 630 series and 24 specifications of copper and aluminum continuous extrusion and coating complete sets with more than 30 patented technologies equipment. Passed ISO9001 quality system certification and EU safety CE certification, it has supplied more than 1,500 production lines for domestic and foreign users, and its products are sold in 29 domestic provinces, municipalities and autonomous regions, and exported to 52 in Asia, Europe, America, Australia and Africa. country and region.