Continuous Extrusion Production Line for Aluminum Conductor

1. The Continuous Extrusion Production Line for Aluminum Conductor can set different extrusion processes, and use the follow-up and fixed needle methods to extrude pipes with different diameters

2. Continuous Extrusion Production Line for Aluminum Conductor has a reasonable tool design, which can greatly reduce the production cost

3. The Continuous Extrusion Production Line for Aluminum Conductor equipment has good sealing performance, low temperature rise, and is reliable and sensitive.

Main uses of Continuous Extrusion Production Line for Aluminum Conductor:

Production of aluminum flat wire, aluminum round wire, sector conductor, ACCC special-shaped aluminum conductor, etc.

Specifications of Continuous Extrusion Machine for Aluminum Round Wire:

| Model | LLJ350 | LLJ400 |

| Nominal diameter of extrusion wheel (mm) | 350 | 400 |

| product category | Sector/shaped conductor | Aluminium platoon |

| Main motor power (kW) | 160 | 250 |

| Aluminum rod diameter (mm) | 2×9.5/15 | 2×15/15 |

| Maximum width of product (mm) | —— | 170 |

| Product cross-sectional area (mm2) | 25~300 | 75~2000 |

| Productivity (kg/h) | 260 | 600/900 |

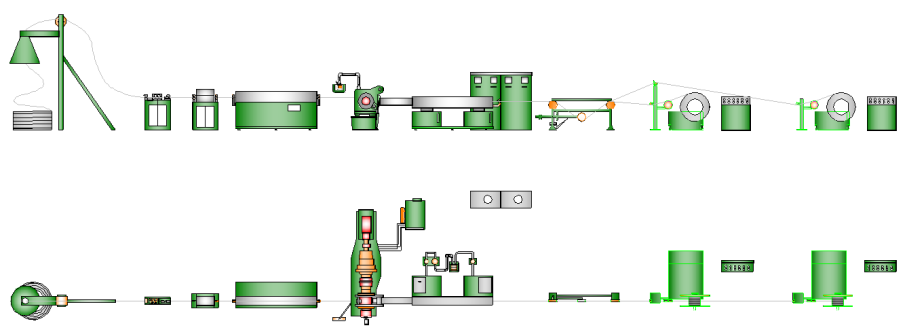

Line layout of the Continuous Extrusion Machine for Aluminum Round Wire:

Our advantage:

Technological innovation has always been the driving force behind our progress. We use various advanced technological means to conduct in-depth and thorough research on the continuous extrusion process.

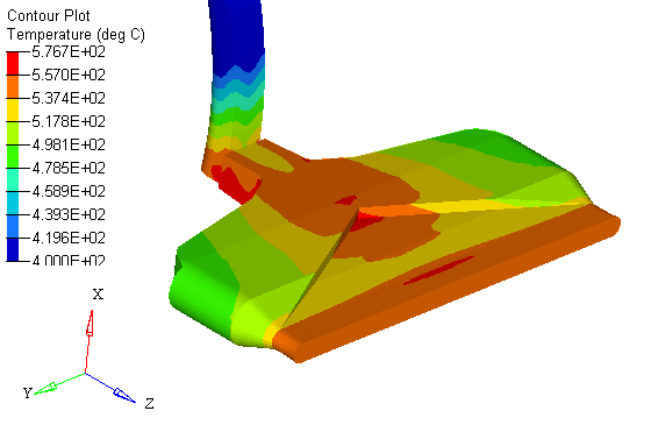

The advanced plastic forming numerical simulation software is used to analyze the velocity field, stress field and temperature field of the metal material in the continuous extrusion deformation zone, and the loads of the equipment and tools are determined accordingly. So as to ensure the reliability of the design

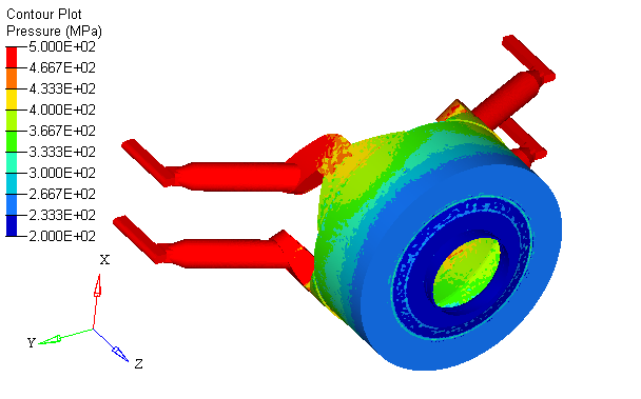

Using 3D design software, the structural design of the host and tooling is carried out, and the finite element strength calculation is carried out for the main stress components, thus ensuring the high level of design.