Conform Machine for Aluminum Tube

1. The Conform Machine for Aluminum Tube can set different extrusion processes, and use the follow-up and fixed needle methods to extrude pipes with different diameters

2. Conform Machine for Aluminum Tube has a reasonable tool design, which can greatly reduce the production cost

3. The Conform Machine for Aluminum Tube equipment has good sealing performance, low temperature rise, and is reliable and sensitive.

Use of Conform Machine for Aluminum Tube:

It can produce round tubes for evaporators of refrigerators and freezers, and perforated tubes for automobile air conditioners and intercoolers.

Specifications of Continuous Rotary Extrusion Line for Tube:

| Model | LLJ300 | LLJ300B | LLJ300H |

| Nominal diameter of extrusion wheel (mm) | 290 | 310 | 290 |

| Main motor power (kW) | 110 | 132 | 110 |

| Aluminum rod diameter (mm) | 9.5 | 12 | 9.5 |

| Diameter of aluminum round pipe (mm) | 5~20 | 5~20 | 5~20 |

| Width of flat aluminum tube (mm) | - | ≤40 | ≤40 |

| Productivity (kg/h) | 160 | 190 round/140 flat | 240 |

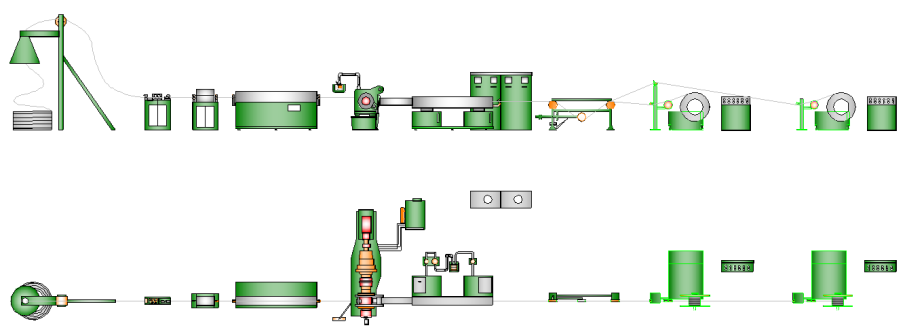

Line layout of the Continuous Rotary Extrusion Line for Tube:

Our spare parts:

Tooling accessories and molds (extrusion wheel, cavity, mold, guide plate, compaction wheel...): using high-quality steel at home and abroad, relying on the forging advantages of Dalian Heavy Industry Base, using the company's unique heat treatment process and vacuum furnace to ensure accessories Long service life, using high-quality brand machining centers, CNC machine tools and electrical processing equipment to ensure the accuracy and quality of accessories.

After-sales service

Dalian Konform Technology Co., Ltd. has a high-quality customer service team, which is closely connected and communicated from installation and commissioning to after-sales service, quickly solves customers' equipment and process problems, shares the latest research and development results in a timely manner, and accurately provides various tooling accessories, Finished molds and all accessories for continuous extrusion presses.