Aluminum Rod Continuous Casting Machine

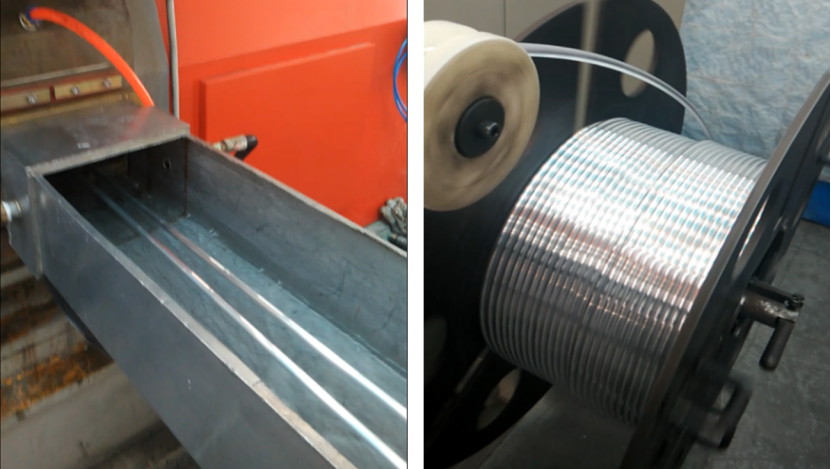

1.Aluminum Rod Continuous Casting Machine is continuous casting and continuous extrusion line production, the process is short

2.Aluminum Rod Continuous Casting Machine can make efficient use of casting waste heat with low energy consumption

3. Aluminum Rod Continuous Casting Machine can have strong shear deformation and grain refinement

4. The products of Aluminum Rod Continuous Casting Machine are provided in rolls with good quality

Uses of Aluminum Rod Continuous Casting Machine:

Production of aluminum strontium, aluminum titanium boron and other intermediate alloy gold coils, wire rods

Specifications of Aluminum Rod Continuous Casting Machine:

| Model | CCE400 | CCE500 |

| Diameter of crystallizer wheel of caster (mm) | 1200 | 1400 |

| Diameter of crystallization wheel (rpm) | 2.5 ~ 3.7 | 1.6 ~ 2.3 |

| Sectional area of ingot (mm2) | 730 | 1000 |

| Output speed of ingot (m/min) | 8.5 ~ 12.7 | 7.2 ~ 10.2 |

| Nominal diameter of extrusion wheel (mm) | 400 | 500 |

| Extruder power (kw) | 250 | 400 |

| Product diameter (mm) | 8 ~ 12 | 8 ~ 15 |

| Yield (kg/h) | 700 | 900 |

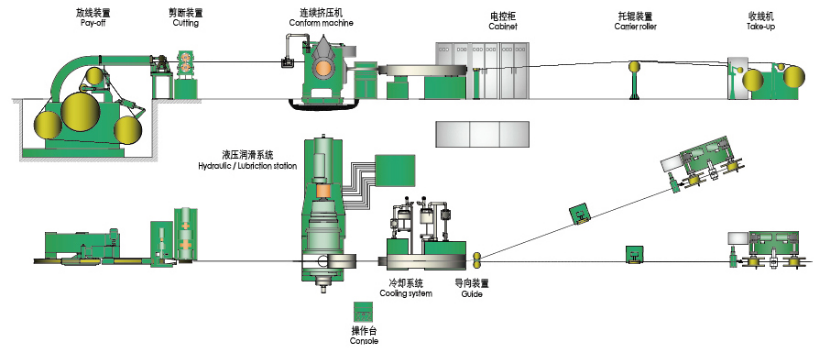

Production line layout of Aluminum Rod Continuous Casting Machine:

Aluminum Rod Continuous Casting Machine Production Process:

The high-temperature molten steel is continuously poured into one or a group of water-cooled copper molds, and the molten steel gradually solidifies along the periphery of the mold into a billet shell. The billet is pulled out, and the billet is completely solidified by water spray cooling in the secondary cooling zone, and is cut to length by the cutting device according to the requirements of rolling. This process of directly pouring high-temperature molten steel into billets is called continuous casting. Its appearance has fundamentally changed the ingot-rolling process that has dominated for a century. Because it simplifies the production process, improves the production efficiency and metal yield, saves energy consumption, greatly reduces the production cost, and has the advantages of good billet quality and other advantages. In today's steelmaking enterprises, whether it is long-process steelmaking or short-process steelmaking, the equipment of continuous casting machines is almost inevitable.

About our corporate values:

Integrity is the instant of Konform. It is not only the professional ethics of business operation, but also the core value of our life. We treat every customer, partner and employee honestly, strictly abide by the contract, and use the highest standards of public morality and social ethics. Always review and standardize our business conduct.

Look forward to working with you!