Aluminum Hollow Tube Extrusion Machine

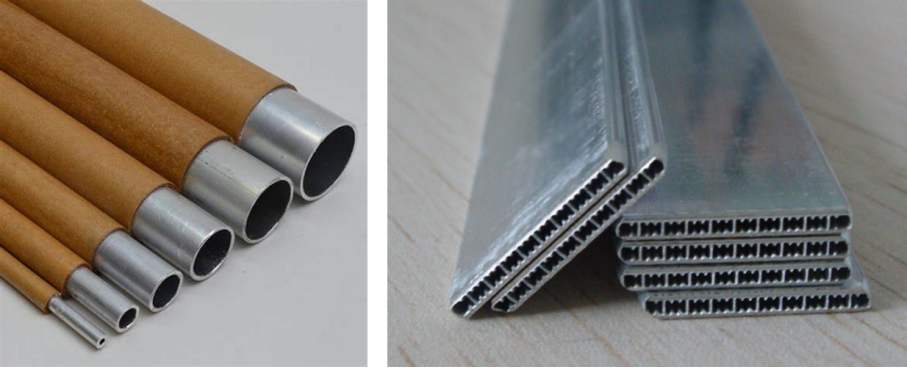

1. The Aluminum Hollow Tube Extrusion Machine can set different extrusion processes, and use the follow-up and fixed needle methods to extrude pipes with different diameters

2. Aluminum Hollow Tube Extrusion Machine has a reasonable tool design, which can greatly reduce the production cost

3. The Aluminum Hollow Tube Extrusion Machine equipment has good sealing performance, low temperature rise, and is reliable and sensitive.

Main uses of the Aluminum Hollow Tube Extrusion Machine:

Production of round tubes for refrigerators and freezers evaporators, and multi-hole tubes for automotive air conditioners and intercoolers

Specifications of Aluminum Hollow Tube Extrusion Machine:

| Model | LLJ300 | LLJ300B | LLJ300H |

| Nominal diameter of extrusion wheel (mm) | 290 | 310 | 290 |

| Main motor power (kW) | 110 | 132 | 110 |

| Aluminum rod diameter (mm) | 9.5 | 12 | 9.5 |

| Diameter of aluminum round pipe (mm) | 5~20 | 5~20 | 5~20 |

| Width of flat aluminum tube (mm) | - | ≤40 | ≤40 |

| Productivity (kg/h) | 160 | 190 round/140 flat | 240 |

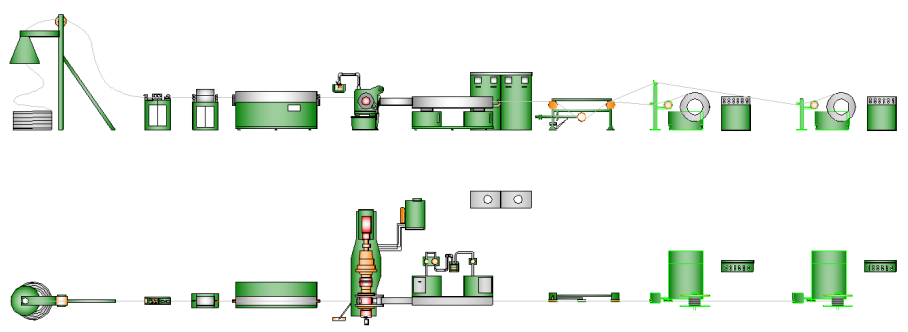

Line layout of the Aluminum Hollow Tube Extrusion Machine:

Our advantage:

Technological innovation has always been the driving force behind our progress. We use various advanced technological means to conduct in-depth and thorough research on the continuous extrusion process.

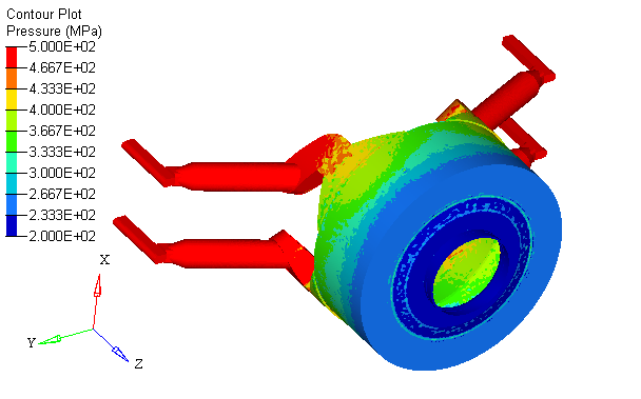

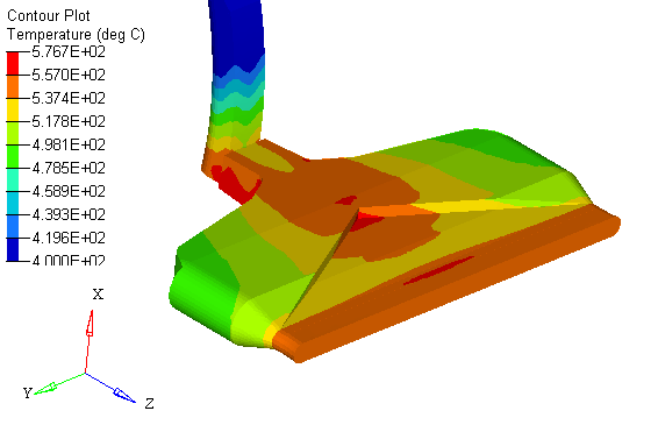

The advanced plastic forming numerical simulation software is used to analyze the velocity field, stress field and temperature field of the metal material in the continuous extrusion deformation zone, and the loads of the equipment and tools are determined accordingly. So as to ensure the reliability of the design

Using 3D design software, the structural design of the host and tooling is carried out, and the finite element strength calculation is carried out for the main stress components, thus ensuring the high level of design.

Originally established in 1993, Dalian Konform Technical Company, Ltd. is a world-leading provider of the continuous extrusion technology and equipment. Our research and development history in this area dated back to 1984. In over thirty years, we have provided highly efficient solutions for continuous extrusion, continuous cladding and continuous sheathing to our clients in the field of non-ferrous metal processing and cable manufacturing.

Building on over thirty patented technical innovations, Dalian Konform have developed twenty-four different models under three product categories (continuous extrusion, continuous cladding and continuous sheathing for copper and aluminum). We are certified to ISO 9001 standard and our products comply with EU CE marking. As of 2020, we have designed and manufactured more than 1500 production lines for our clients in 52 countries covering all six continents. They are widely used to produce AS wire, OPGW, aluminum sheathing of power cable, copper flat wire, copper bus bar, copper strip blank, aluminum tube, aluminum conductor etc.