New technology of high-voltage cable aluminum sheath - Dalian Konform develops SSLB500 for Furukawa

On March 23, 2021, the internationally renowned wire and cable journal "Wire" published an article introducing the SSLB500 EHV cable aluminum sheath continuous coating production line developed by our company. The translation is as follows:

New Technology of High Voltage Cable Aluminum Sheath

——Dalian Konform developed SSLB500 for Furukawa

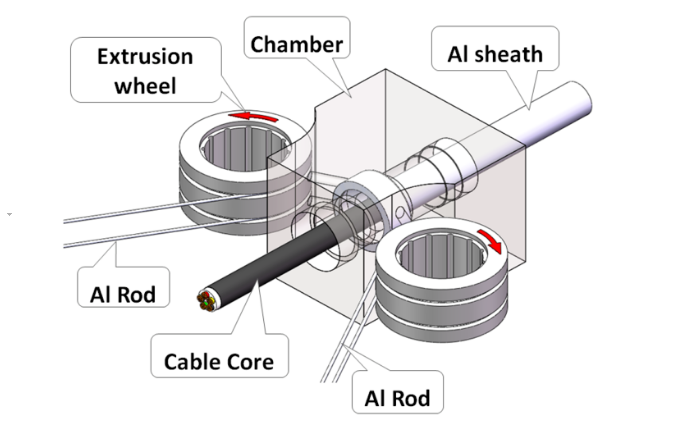

Two extrusion wheels drive four rods into the cavity, forming a sheath on the outside of the cable

Dalian Konform applied its latest research and development results to the SSLB500 continuous cladding production line designed for Furukawa, using four rods to extrude the corrugated aluminum sheath of the ultra-high voltage cable. Mass production shows that the product shows good performance in terms of forming stability, production efficiency, aluminum sheath quality, and power consumption.

In recent years, the production of EHV cable aluminum sheath has adopted a continuous coating process. In the previous process, two rods were fed into double grooves on an extrusion wheel, resulting in a double channel continuous wrap. This cladding supports products with a maximum diameter of 165mm. However, once the diameter of the sheath product exceeds 120mm, problems such as short tool life, complex mold design, high extrusion pressure, and poor forming stability will occur. Most of these problems are caused by asymmetric mold structures and complex metal flow.

Researchers at Dalian Konform have developed a new vertical "four-channel" cladding process. Two double-groove extrusion wheels are used to rotate synchronously to drive the four rods into the cavity through the corresponding channels, join together under high temperature and high pressure, and extrude through the annular die to form a sheath layer outside the cable. The working range of this process is 60mm-180mm in diameter and 2mm-8mm in wall thickness.

The mass-produced 66kV/400mm2, 110kV/1000mm2, 220kV/2500mm2 high-voltage power cables perform well in terms of forming stability, production efficiency, aluminum sheath quality, and power consumption. The roundness of the extruded aluminum tube reaches 99%, and the thickness deviation is within ±5%. When the spindle runs between 6-7.5 rpm and the flash rate is around 5%, the average output of the aluminum sheath is 738 kg/h, and the average energy consumption is 440 kWh/ton.

"The success of the SSLB500 proves that the 'four-channel' sheath process is superior to previous processes on the market," said Mr. Fan Zhixin, general manager of Dalian Konform. "We are currently further developing other cable products, such as aluminum jackets for superconducting Rutherford cables, and we are happy to develop new production lines to meet our customers' requirements."

"Wire" is the most well-known English-language journal in the international wire and cable field.