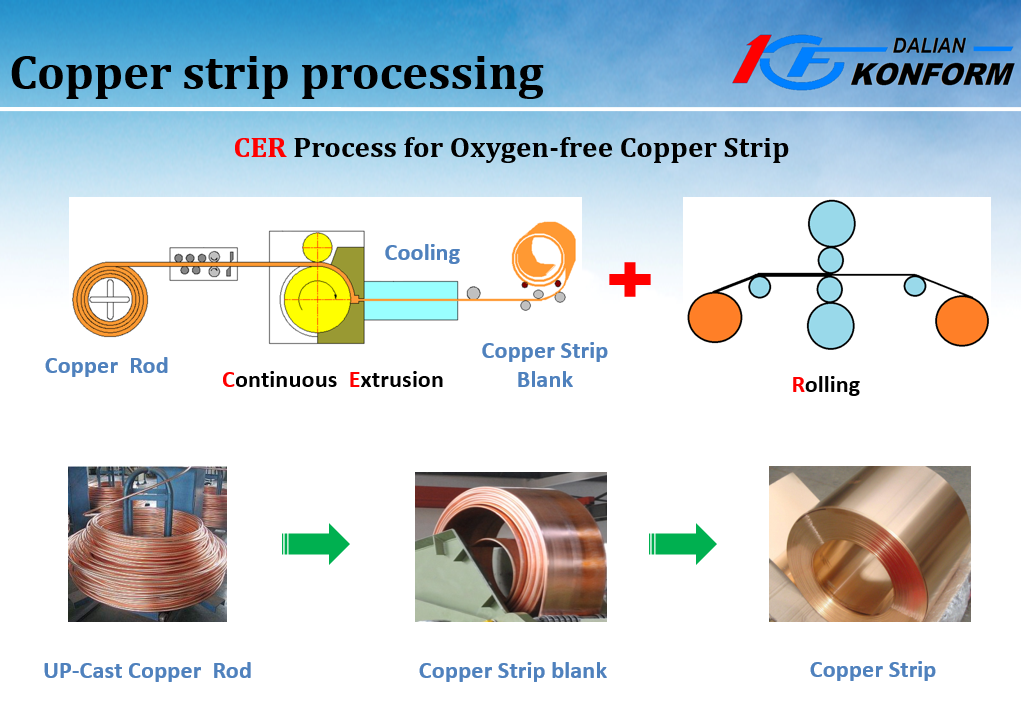

Continuous Extrusion Line For Copper Strip Blank

Technical Agreements

I. Advantages of new automatic continuous extrusion production line:

1. This production adopts 30mm pure copper rod to produce copper strip base with maximum width <420mm.

2. It contains 11 patented technologies to achieve super wide extrusion of copper strip base, maximum width is 420mm.

3. High productivity, low energy consumption and low cost: the average output of continuous extrusion production line of copper strip base is 2-2.8tons/h, and the production consumption is below 120-150kwh/ ton.

4. High automation, high reliability: extremely low failure rate, safe and reliable operation, easy maintenance.

5. High information and intelligence, remote wireless Internet service and monitoring.

6. Energy management system, to minimize the power consumption of equipment operation.

II Main technical specifications and requirements of production line

TLJ630U continuous extrusion production line adopts radial extrusion mode, use F30mm T2 Oxygen-free upcast copper rod to extrude 14.5x420mm copper strip base product.

1. Main Technical Parameter of production line:

1) The Center Height: 1200mm.

2) Direction: confirmed by users